Manganese-based Phosphating Coating Agent For Oilfield Drilling

- BT

- SHENYANG

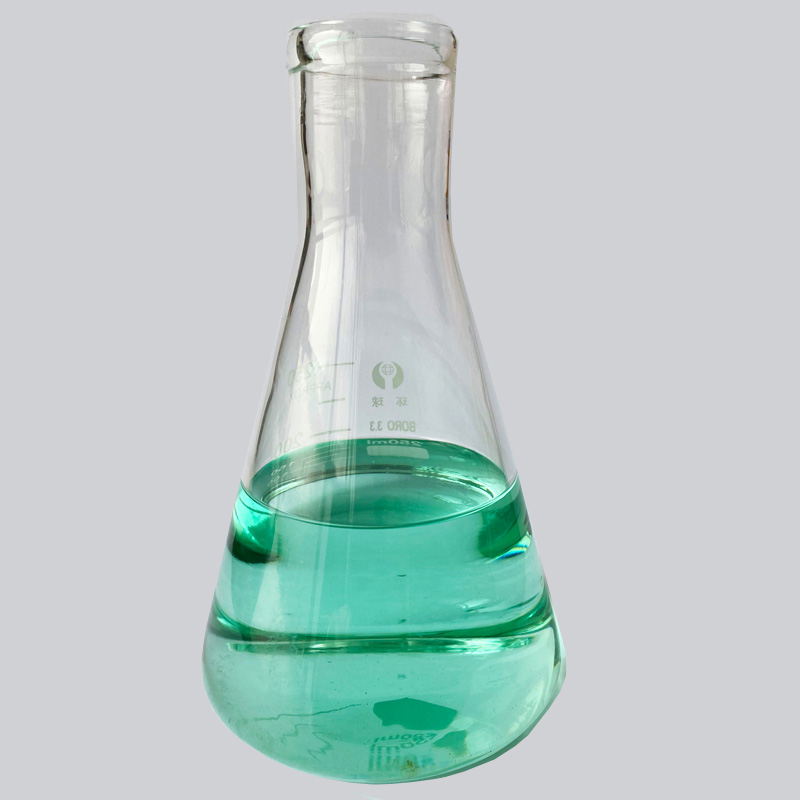

manganese-based phosphating BT-3601 is a manganese-based phosphating coating agent widely used on heavy-duty anti-corrosion and wear-reducing workpieces.

The product has the characteristics of fast film-forming speed, small amount of residue, and easy management. After the treatment of this product, uniform crystallization and fine gray-black to black phosphating film can be obtained on the surface of the workpiece. The phosphating film can better absorb grease and make the workpiece have good corrosion resistance and wear resistance.

Phosphating agent BT-3601 is suitable for treatment by dipping.

Phosphating agent bt-3601 is a manganese-based phosphating coating agent widely used on heavy-duty anti-corrosion and wear-reducing workpieces. The product has the characteristics of fast film-forming speed, small amount of residue, and easy management. After the treatment of this product, uniform crystallization and fine gray-black to black phosphating film can be obtained on the surface of the workpiece. The phosphating film can better absorb grease and make the workpiece have good corrosion resistance and wear resistance.

Phosphating agent bt-3601 is suitable for treatment by dipping.

Tank replenishment and adjustment: (Take 1000L treatment liquid as an example):

1. Total Acidity:

With the progress of production, the total acidity of the treatment solution will gradually decrease, so it should be replenished in time. In general, agent C should be added when water is added; agent C and agent F should be added in proportion to consumption during production. For every 2.5-3.0kg of phosphating agent added, the total acidity point will increase by one point. Under normal circumstances, the ratio of agent C and agent F is about 1:2-3. Due to the different actual conditions of each production line, the ratio of agent C and agent F will be different. The on-site engineer of Company will give the addition according to the specific situation Proportion.

2. Fe++ content:

With the progress of production, the content of ferrous iron in the treatment bath will gradually increase. When the Fe++ content of the treatment bath is btose to the upper limit of the specified concentration, the phosphating film will be rough, thereby affecting the performance of the phosphating film. tank” or reconstitute the bath solution.