Powder Cleaner For Steel Strips

- BT

- SHENYANG

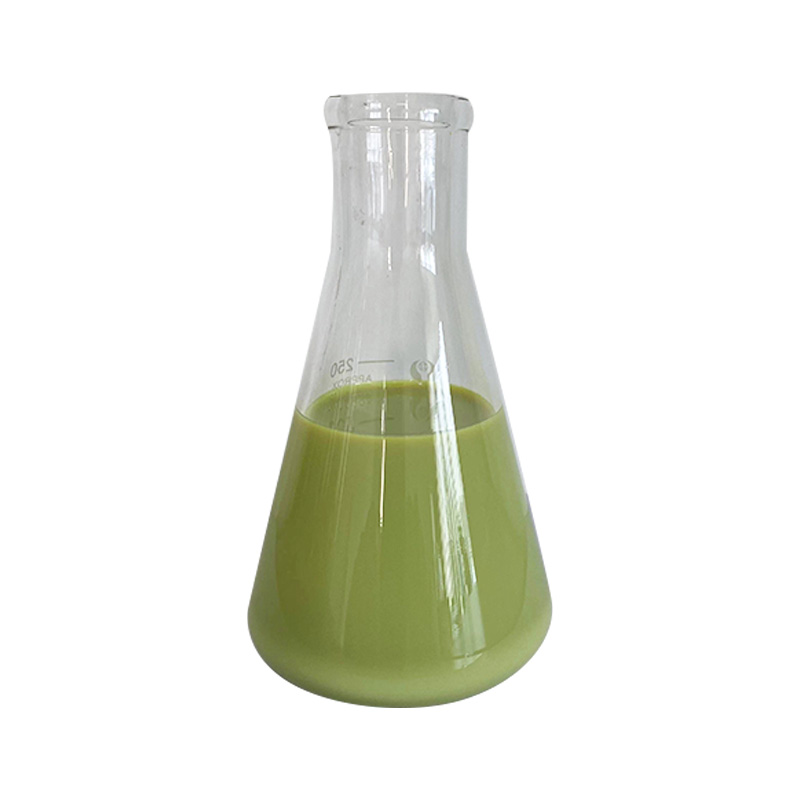

cleaner for annealing plate is an alkaline degreasing powder agent. .It is suitable for chemical degreasing of electroplating or electroless plating. it also can be used for cleaner for electrical steel.

as a cleaner for strip steel, It has a good cleaning effect on all kinds of organic oil, mineral oil, rolling oil and dirt.

This product has the advantages of fast degreasing, simple operation and convenient management. Treatment methods can be spraying, dipping and other methods.

Galvanized powder degreasing agent is an alkaline degreasing agent composed of a variety of alkali, surfactant and water treatment agent. Chemical degreasing suitable for electroplating or electroless plating

Two, groove matching method:

4. Fill the treatment tank with 80% water.

5. Add galvanized powder degreaser to the premixed tank, completely dissolve, add it to the treatment tank according to 1% concentration, and the free alkalinity is about 10 points after adding.

(Add defoaming agent according to the production situation)

6. Add water to the working liquid level, stir thoroughly, and heat to the required temperature.

4. Treatment conditions:

(1) Treatment temperature :20~50℃.

(2) Free alkalinity :15-35 Pt (can be adjusted as required)

Management specification

1. With the progress of production, the free alkalinity of the treatment liquid will gradually decrease, and attention should be paid to the addition of degreasing agent at any time. The degreasing agent will rise a point if it is added 1-1.2kg/T galvanized powder degreasing agent per tank ratio. (The amount will vary depending on the oil.)

2. After the working liquid is used for a period of time, the oil will gradually accumulate and affect the cleaning effect, so the working liquid should be scrapped and reformulated to ensure the cleaning effect. (Normally, when the total alkalinity and free alkalinity differ by a factor of 2, the tank should be abandoned and the tank should be cleaned. For different tanks, different treatment.)

3. After cleaning the workpiece, must be thoroughly rinsed with clean water residual degreaser, rinsing water should overflow at a certain rate to ensure the clean water quality.

Equipment requirements: Tanks, pipes and pumps used in this process can be made of low carbon steel.

Packing: 25kg/ woven bag; Shelf life: six months

Operation notes: This product is a strong alkaline chemical, the eyes and skin have certain corrosion, must wear a mask, rubber gloves when using.

Powder spraying common problems and solutions

1, dusting indoor impurities, mainly dust, clothing fibers, equipment particles and dusting system scaling. The solution is to blow out the duster system every day before work, and thoroughly clean the duster system and duster room with a damp cloth and vacuum cleaner

2, powder impurities, mainly powder additives too much, uneven pigment dispersion, powder extrusion caused by powder, etc., the solution is to timely clean the phosphating tank and spray tube slag, control the concentration and proportion of phosphating tank

3, water quality impurities, mainly used in the pre-treatment of water sand, salt content caused by excessive impurities, the solution is to increase the water filter, the use of purified water for the last two levels of clean water.

4, phosphating film yellow, flower or local no phosphating film caused by poor adhesion, the solution is to adjust the phosphating tank concentration and proportion, improve the phosphating temperature.

5, workpiece edge and corner moisture drying caused by poor adhesion, the solution is to increase the drying temperature